Lenovo ESG

In-house Operations

Our Approach

At Lenovo, we see the safety and well-being of our workforce as integral to our long-term success. What helps us in this area is that, unlike other major technology companies, we conduct more than 50% of our manufacturing in our own factories. This model enables us to better control our sustainability footprint, while bringing innovation to market more efficiently.

Our strategy, including performance and engagement programs, for ensuring a safe, healthy workplace is detailed below.

-

Occupational Health & Safety (OSH)

-

Health & Safety Performance

-

Compliance Management

-

Communication & Employee Engagement

-

Prevention & Control

Occupational Health & Safety (OHS)

Lenovo adheres to international standards for workplace safety through its Occupational Health and Safety (OHS) Management System*. Lenovo’s global manufacturing sites are ISO 9001:2015 (Quality), ISO 14001:2015 (Environmental), and ISO 45001:2018 (OHS) certified by accredited third parties. As required by these internationally accepted standards, the management of objectives and targets at each certified site continually fosters a safe and healthy work environment for employees.

The OHS Management System is also evaluated in the scope of Lenovo’s global risk registration process as part of its Enterprise Risk Management (ERM) program. The ERM program is designed to enable effective and efficient identification, and management’s visibility into critical enterprise risks, including health and safety. Through a process of planning, education, controls, performance evaluation, and continuous improvement, health and safety programs are assimilated throughout Lenovo’s global manufacturing footprint.

OHS Management System Implementation

Each year, Lenovo keeps a very low incident rate. These programs are included in the implementation of our OHS management.

Compliance management

Lenovo has an established process with assigned responsibilities for identifying and evaluating compliance with national, provincial, and local OHS legal and other requirements. Each manufacturing site must research and establish an inventory of applicable OHS legal and other requirements, which must be updated regularly. Compliance with these requirements is regularly evaluated and mitigation action is carried out when necessary. These applicable requirements are considered as Lenovo establishes, implements, maintains, and continually improves its OHS management system.

Applicable OHS legal and other requirements are categorized in accordance with how these requirements impact actual operations and functions performed at Lenovo. These operations and functions have been broken down into different categories, which include but are not limited to: Workplace Safety, Hazard Chemical Safety, Electrical Safety, Fire Safety, Process Safety and Risk Assessment, Health Services, and Emergency Response.

Hazard identification and risk assessment

One of the characteristics of the OHS management system is risk-based thinking. Hazard identification and risk assessment are always important inputs for work-related injury and ill health prevention, and operational controls. Lenovo has implemented a comprehensive hazard identification and risk assessment program that assesses the activities and projects throughout its operations. The program offers a comprehensive procedure for identifying health and safety hazards, assessing their impact on employees and the sites, recommending corrective actions, tracking required responses, and communicating the resolution of challenges. This strategy is one method employed to safeguard the health and safety of employees by identifying precautionary measures that prevent work-related injuries.

In FY 2024/25, Lenovo undertook various initiatives, such as an annual hazard identification and risk assessment, new equipment risk assessment, and more.

Health and safety awareness, and communication

Lenovo fosters a culture that values health and safety. Employee participation is essential to the success of health and safety management. The employee and/or contractor health and safety awareness programs include, but are not limited to:

- New employee orientation: A presentation or video that covers topics such as health and safety legal requirements, workplace hazards, emergency procedures, and employees’ health and safety obligations. Additionally, new employees may participate in safety training sessions per local requirements.

- Topic-specific training: Topics such as health and safety awareness, emergency response, electrical safety, chemical handling, machine guarding, breast cancer awareness, mental health, stress and emotion management, dental health, and more.

- Promotion activities: Activities including Safety Month, ESG Month, Health Week, Well-being Week, newsletters, safety talks and more.

Emergency brigade training at manufacturing site in Indaiatuba, Brazil in October 2024

Prevention and control

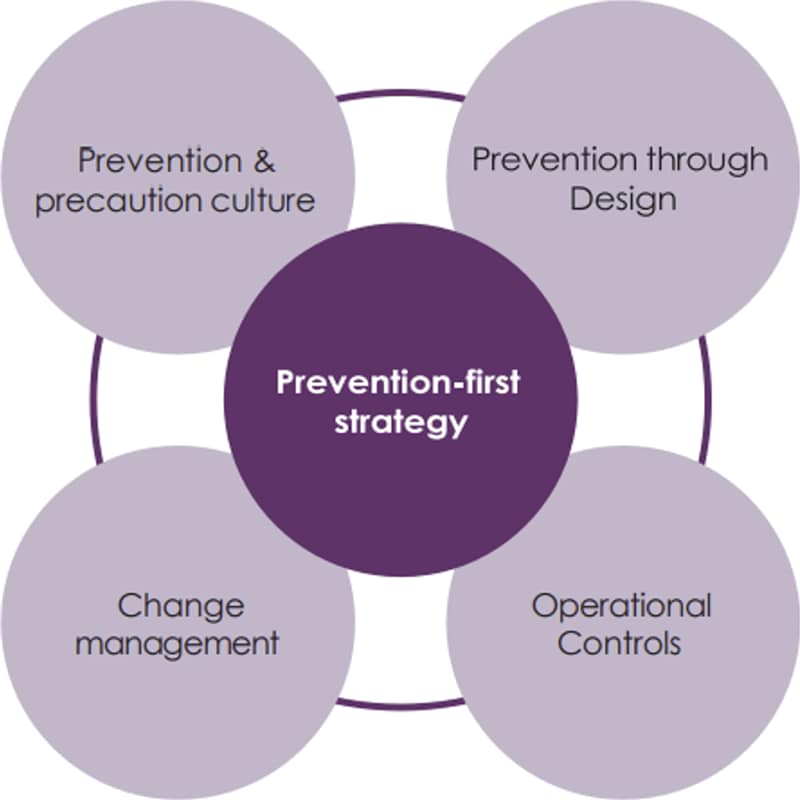

Lenovo’s health and safety program prioritizes prevention, incorporating health and safety-related standards at the earliest stage of a facility development or at the earliest stage of any changes that can result in risks. In FY 2024/25, consistent with the concept of ‘Prevention Through Design’, an ergonomics guideline was formulated to provide manufacturing sites with practical guidance for the design or upgrading of manual workstations, identification of ergonomics-related hazards, and improvement options, thereby preventing discomfort and injuries associated with work activities.

Furthermore, a comprehensive Health Management System (HMS) framework was established, encompassing both occupational health services and voluntary health promotion services. An HMS diagnosis tool based on the framework was developed to assist LME manufacturing sites to evaluate the maturity of their HMS, including promoting mental and physical health among the workers, so as to proactively enhance HMS practices among all manufacturing sites.

Performance evaluation

Management assesses the performance of its manufacturing sites to ensure health and safety objectives are being met. These evaluations consist of:

- Conducting monthly assessments of health and safety KPI performance to ensure the sites are on track, correct any identified deviations, and help meet the targets as needed;

- Organizing a monthly global manufacturing ESG meeting to share updates on manufacturing site performance, best practices, and lessons learned;

- Conducting quarterly LME ESG Committee review meetings;

- Conducting internal audits of manufacturing sites, including site self-assessments; and

- Organizing periodic management reviews for each manufacturing site.

Incident investigation and corrective action

Lenovo strives to maintain a workplace that is accident and injury-free. When a work-related injury, illness, or near-miss incident occurs, departmental managers and the OHS team immediately launch an investigation into the incident to identify the root cause. Corrective action plans are then formulated, and implementations are tracked until closure.

Additionally, the OHS team engages in a ‘Lessons Learned’ process that includes sharing information and analyzing data with other manufacturing locations, and holding lessons learned meetings to increase awareness and prevent repeated incidents.

Emergency preparedness

Lenovo recognizes the importance of developing and implementing an emergency plan that protects people involved in its manufacturing processes and ensures that employees are familiar with its emergency response procedure. Each site has designed an emergency plan that specifies the appropriate response to unexpected events, minimizes related risks, and ensures the safety of employees. This process is further supplemented by providing skills that include first aid and cardiopulmonary resuscitation (CPR) training. To further enhance preparedness, several manufacturing sites have applied digital applications to enhance emergency response efficiency and emergency management.

Certification and audits

Lenovo is determined to ensure that the working conditions at all its manufacturing sites are safe, workers are treated with respect and dignity, operations are environmentally sound, and business operations are conducted responsibly and ethically. In support of this commitment, Lenovo has implemented programs and practices to ensure that its manufacturing sites comply with the RBA Code of Conduct.

Additionally, Lenovo continues to work to achieve and maintain RBA Validated Assessment Program (VAP) and Factory of Choice (FoC) recognitions at its manufacturing sites as it aims to demonstrate social and environmental leadership. Lenovo also conducts internal audits, ISO certification audits, and customer requested audits.

During the RBA VAP assessments, independent auditors assess the sites’ labor, health and safety, environment, ethics, and supply chain management practices in addition to other ESG-related topics.

The RBA FoC designation is intended to recognize manufacturing sites that fully commit to the RBA Code of Conduct and demonstrate leadership through impact and transparency. To enter the FoC program, manufacturing sites must complete an evidence-based application that is reviewed by RBA staff to ensure the program’s criteria are met. As of the end of FY 2024/25, Lenovo’s manufacturing sites in Brazil, China (Hefei, Shenzhen, Tianjin, Wuhan), Hungary, India, Japan, Mexico, and the US have achieved platinum, gold, or silver recognitions for RBA VAP and also achieved RBA FoC recognitions.

Recognitions

In May 2024, Lenovo’s manufacturing site in Wuhan, China, was honored with the “National Excellence Case of Healthy Enterprise Establishment” by the National Health Commission, in recognition of its exemplary performance in occupational health management, which included notable achievements in areas such as mental health support, chronic disease management, and the mitigation of occupational hazards.

In December 2024, one production line at Lenovo’s manufacturing site in Hefei, China, was awarded the designation of “Class II of Safety Management Standardized Working Team” by China Association of Work Safety, in recognition of its outstanding performance and innovative practices in workplace safety.

In December 2024, Lenovo’s manufacturing site in Shenzhen, China, was awarded the “Excellent Case of Family-Friendly Workplace” by Shenzhen Women and Children’s Development Foundation. This recognition acknowledges the company’s support and investment in family-friendly aspects as it relates to the workplace, and its efforts to create a work environment that facilitates work-family balance and the early development of employees’ children.